| model | TPP900-1 | TPP900-2 |

| capacity | 750-900cups/hour | 1500-1800cups/hour |

| voltage | 220V/110V | 220V/110V |

| power | 1.2KW | 2.4kw |

| Working air pressure | 0.5MPa-0.75 Mpa | 0.5MPa-0.75 Mpa |

| Max. air consumption | 0.45m3/minute | 0.45m3/minute |

| Dimension | 850*950*1650mm | 850*950*1650mm |

| Weight | 350KG | 420kg |

Product Description

Introduction:

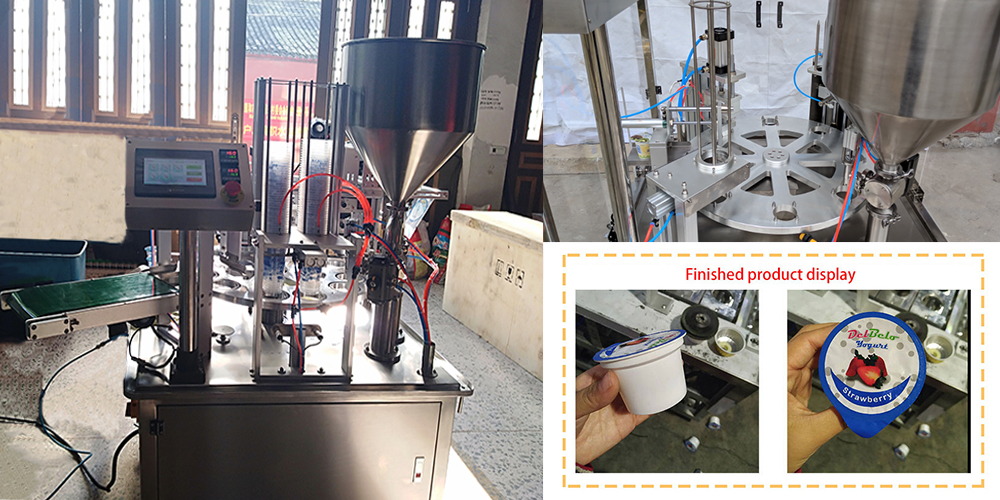

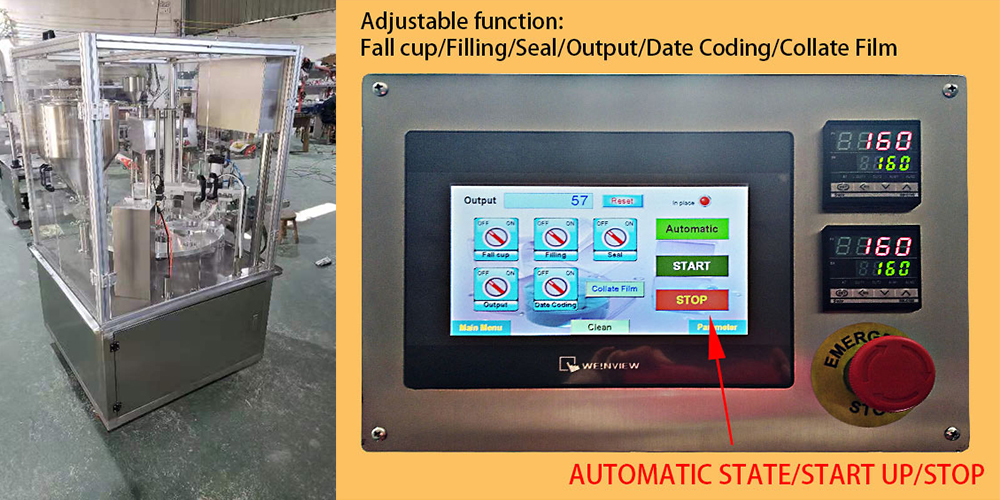

This automatic cup filling and sealing machine can realize auto cup dropping, filling, sealing and auto cup discharging function. The machine adopts stainless steel body, which meets the sanitary requirements and is convenient for cleaning.

Work flow:

Automatic cup dropping → quantitative filling → photoelectric detection sealing and film cutting → conveying

Main functional structure:

1.Transmission and template traction system: including drive motor, reducer, smooth transmission, a linear gap transmission system and a traction transmission chain, a positioning device and an aluminum mold board, etc. There is a stainless-steel plate under the aluminum plate to support the smooth operation of the cup.

2.Automatic cup dropping system: mainly completed by pneumatic device, system by pneumatic components, cup holder, positioning cup dividing device and other components. Stable and efficient.

3.Automatic filling system: Adopting the piston type quantitative filling system and the filling amount can be adjusted.

4.Sealing system: including heating, constant temperature control parts, temperature sensor, sealing device, hot sealing plate and hot sealing head, pneumatic sealing motion executive parts. Sealing temperature: 0-300℃.

5.Automatic cup system: The cup is sucked out and transmitted out automatically.

Product Details